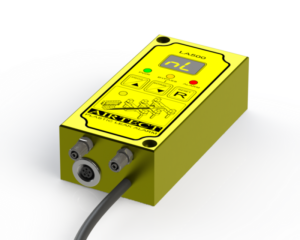

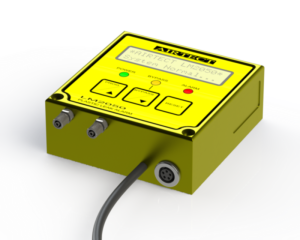

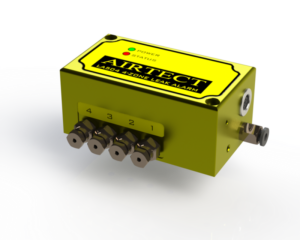

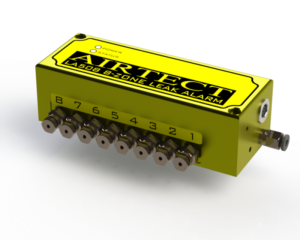

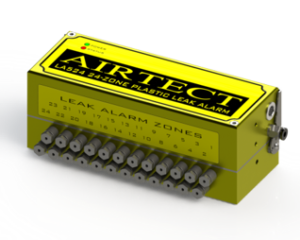

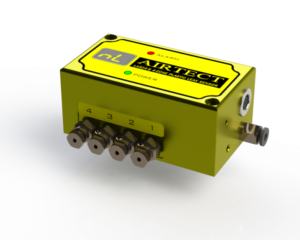

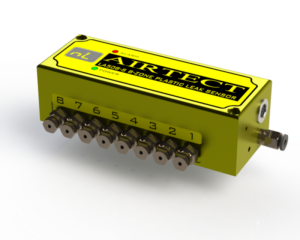

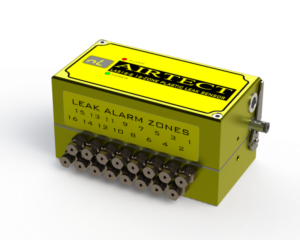

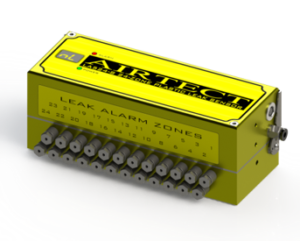

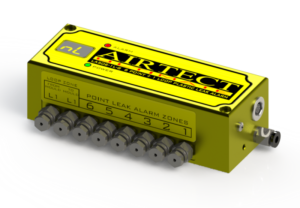

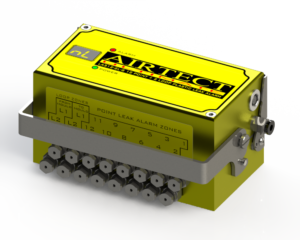

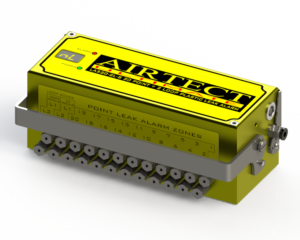

Airtect Plastic Leak Detectors are a unique device which protects from plastic leak damage on either a Hot Runner Mould, the Barrel or the Nozzle.

The design of the Leak Detector allows for the tubing to be easily installed within the existing wiring channels. The LCD display and LED indicator lights sound and display when any plastic is detected near the stainless steel sensor tube. The Leak Detector can also protect against running moulds that are under or over temperature.

This system gives less downtime and greatly reduced repair costs.